Faucet Manufacturing Process

Welcome to our kitchen faucets factory, where we take great pride in producing high-quality kitchen faucets that are both functional and stylish. We are a factory that owns the entire production line, from design to manufacturing, ensuring that every step of the process meets our rigorous standards for excellence. Our team of skilled professionals is dedicated to crafting kitchen faucets that are not only aesthetically pleasing but also durable and reliable. We use only the highest quality materials and the latest technology to create products that are built to last. At our kitchen faucet factory, we are committed to providing our customers with the best possible experience, from the moment they place an order to the moment they install our faucets in their homes. would like to introduce all the faucet production processes to you. Please check each step for how we make a premium kitchen faucet.

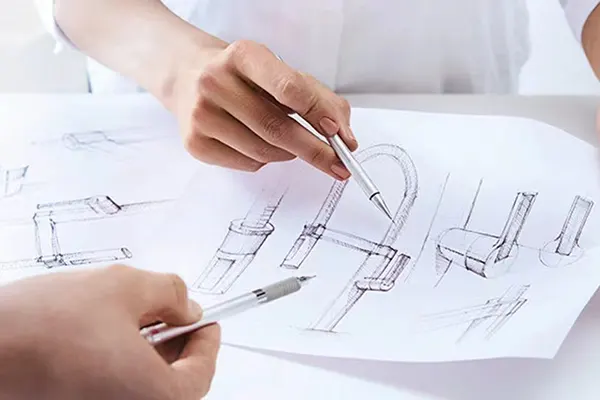

Kitchen faucets Design and Hand drawing

As a leading manufacturer of faucets, we have a design advantage that sets us apart from the competition. Our team of skilled designers is dedicated to creating unique and innovative designs that not only look great but also provide superior functionality. We use only the highest quality materials and advanced manufacturing techniques to ensure that our faucets are built to last. Whether you’re looking for a classic or modern design, we have the perfect faucet to meet your needs

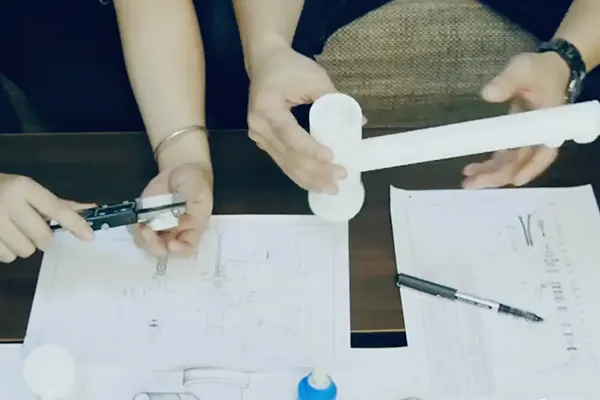

Kitchen faucets 3D printing for Confirming Design

After finalizing the faucet design with our customers, we take the next step to ensure perfection by printing a 3D model for confirmation. This allows us to make any necessary adjustments before moving forward with production, ensuring complete satisfaction from our customers.

Kitchen faucets Lead free Raw Materials

Our kitchen faucets are made from high-quality stainless steel to ensure durability and longevity. This material is known for its resistance to corrosion and rust, making it perfect for a kitchen environment. It also gives a sleek and modern look to your kitchen, adding value and style to your home.

Tubes Cutting

We have the auto cutting machine. Faucet tube cutting is a process used to create precise cuts in metal tubes used for plumbing. The process involves using a specialized Laser Machine cutting to slice through the tube, producing a clean and precise cut. This ensures a secure and leak-free connection between the tube and other plumbing components.

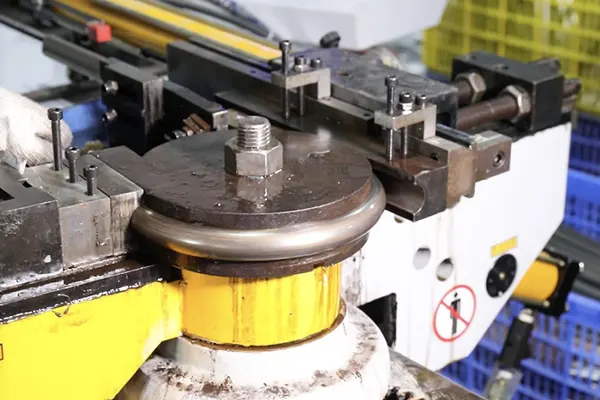

Pipes Bending

We Bending the kitchen faucet spout,Faucets are an essential component of a plumbing system, and the process of bending pipes is critical in their manufacturing. The pipes are bent to fit the required shape and size, and different methods are used, including hot bending and cold bending. Proper bending ensures that the faucet fits perfectly in its intended location and functions correctly.

CNC Machine Processing

We own 10 CNC Machines. Kitchen faucets are often manufactured using computer numerical control (CNC) machining processes. This allows for precise cutting and shaping of the various components, resulting in a high-quality and durable product. CNC technology also allows for intricate designs and customization options.

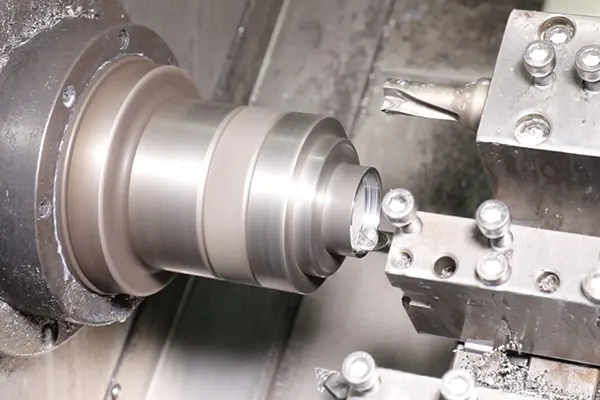

Kitchen faucets Lathe and Drilling

Kitchen faucets undergo a process of CNC Lathe and Drilling, which involves using computer-controlled machines to accurately shape and drill the metal components. This ensures precision and consistency in the manufacturing process, resulting in high-quality faucets that meet industry standards.

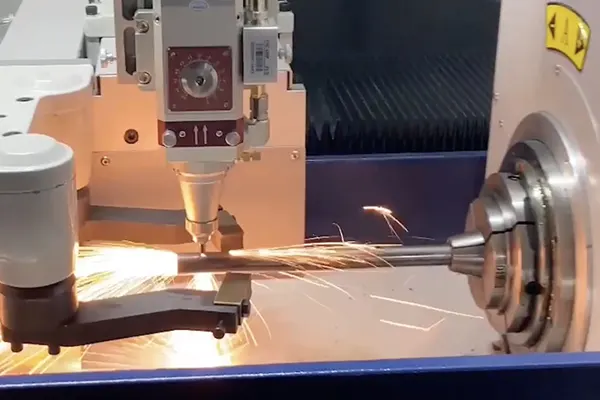

Kitchen faucets Laser Cutting

Laser cutting is an innovative process used in the production of kitchen faucets. The method utilizes a high-powered laser beam to cut through metal, resulting in a precise and clean cut. This allows manufacturers to create intricate and stylish designs that enhance the overall look of the faucet.

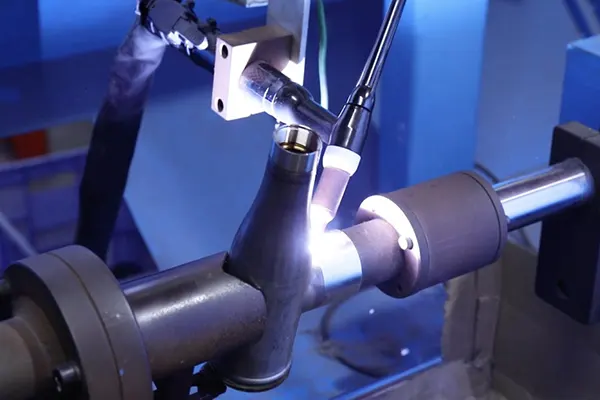

Kitchen faucets Laser Welding

Laser welding is a process used in the manufacturing of kitchen faucets. It involves using a high-powered laser to melt and fuse two or more pieces of metal together. This process creates a strong, seamless bond that is resistant to corrosion and wear, making it an ideal method for producing high-quality faucets that can withstand everyday use.

Kitchen faucets Argon arc Welding(TIG)

Kitchen faucets are often made using the Argon arc welding process (TIG). This method involves using a tungsten electrode to heat the metal and then adding filler material to create a strong, seamless weld. TIG welding produces high-quality and precise results, making it a popular choice for manufacturing kitchen fixtures.

Kitchen faucets Surface Polished

We own a professional team on polished.Surface polishing of kitchen faucets is an essential process that involves smoothening and refining the exterior finish of the faucets. This is done by buffing the surface with abrasive materials and using different techniques to give a shiny and polished look. The process not only enhances the appearance of the faucets but also makes them durable and resistant to corrosion.

Kitchen faucets Colorful Surface

Customized your color acceptable.Kitchen faucets can be finished with either PVD or electroplating. PVD, or physical vapor deposition, uses a vacuum and plasma process to deposit a thin layer of material onto the faucet, while electroplating uses an electrical current to deposit a layer of metal onto the surface. Both processes result in a durable and attractive finish for your kitchen faucet.

Kitchen faucets Air Testing

This step is very important, and other factory did not doAir testing is a crucial process for kitchen faucets as it helps detect any leakage. By conducting this test, manufacturers can ensure that the faucet is functioning optimally, and water is not wasted. It is important to pay attention to this process to ensure the longevity and efficiency of the faucet.

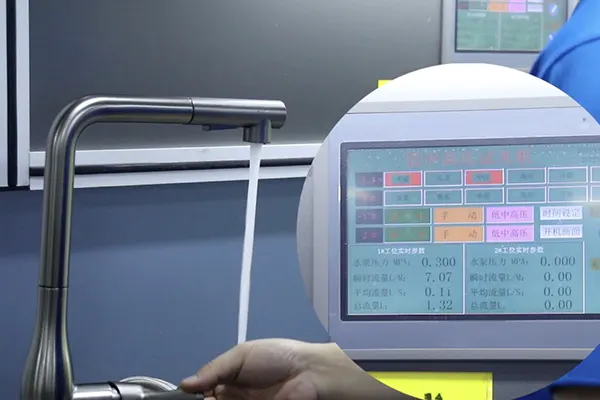

Kitchen faucets Water Testing

Testing the water flow and pressure of kitchen faucets is an essential step to prevent leakage. It ensures that the faucet can handle different water pressures and that there are no leaks in the system. Regular testing also helps in identifying any issues and addressing them before they become bigger problems.

Kitchen faucets Spray and Lifetime Testing Room

We have our own Testing RoomKitchen faucets undergo both salt spray and lifetime testing to ensure their durability and reliability. Salt spray testing exposes the faucets to a corrosive environment to evaluate their resistance to rust and corrosion. Lifetime testing simulates years of use, ensuring that the faucets can withstand constant use without breaking or malfunctioning. These tests ensure that kitchen faucets are of the highest quality and can withstand the demands of daily use.

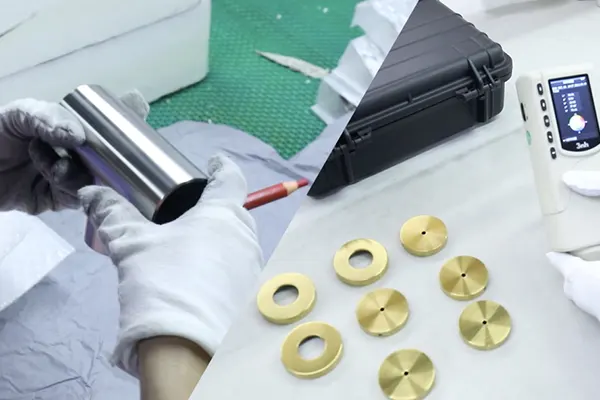

Kitchen faucets QA & QC

We follow the ISO quality control system.Kitchen faucets undergo a rigorous process of quality assurance (QA) and quality control (QC) before they are deemed fit for use. The QA process involves testing for durability, functionality, and safety, while the QC process involves inspecting each faucet to ensure it meets specific design and performance standards. These processes ensure that customers receive high-quality and reliable kitchen faucets that are safe and easy to use.

Kithcen Faucets Assemble

After ensuring all parts are of good quality, we start to assemble them. Kitchen faucets are an essential part of any home’s plumbing system. The process of assembling these faucets involves fitting together various parts, including the spout, handles, valve, and aerator. Once assembled, these faucets are tested to ensure that they function properly and meet industry standards for quality and durability.

Kitchen faucets Packing

The process of packing kitchen faucets involves careful inspection and preparation to ensure that the product is safe and secure during transit. Each faucet is individually wrapped in protective material, such as foam or bubble wrap, and placed in a sturdy box with additional cushioning. The packaging process is crucial to prevent any damage during shipping and ensure that customers receive their faucets in perfect condition.

Kitchen faucets Supply Chain

The kitchen faucet supply chain involves multiple steps, from sourcing raw materials to manufacturing, distributing, and selling the final product. Manufacturers work with suppliers of various components, including brass fittings, ceramic cartridges, and flexible hoses. Distributors play a crucial role in ensuring the faucets reach retailers and consumers. Quality control and sustainability are essential considerations throughout the supply chain.

Kitchen faucets Warehouse

Our company takes pride in having a large kitchen faucets warehouse to support our customers’ businesses. With a wide range of high-quality faucets, we ensure that our customers have the options they need to keep their kitchens running smoothly.

Kitchen faucets Loading

We load containers of high-quality kitchen faucets, ensuring timely delivery and excellent customer service. Our team carefully packages and transports each faucet, ensuring that they arrive at their destination in pristine condition. Trust us for all your kitchen faucet needs.

Consult Your Willing Kitchen faucets Experts

We help you avoid the pitfalls to deliver the quality and value your Kitchen faucet need, on time and on -budget.